Hybridization: Making highly complex solutions accessible for SMEs

CFD simulations often require expertise and costly infrastructure, that’s out of reach for many small and medium enterprises (SMEs) – creating a handicap for them in competing with larger companies.

One of the primary goals of COA-CFD has been – increasing the accessibility of CFD technology for SMEs in design-heavy industries. And a crucial factor that discourages SMEs from using CFD tools is the complexity of its usage.

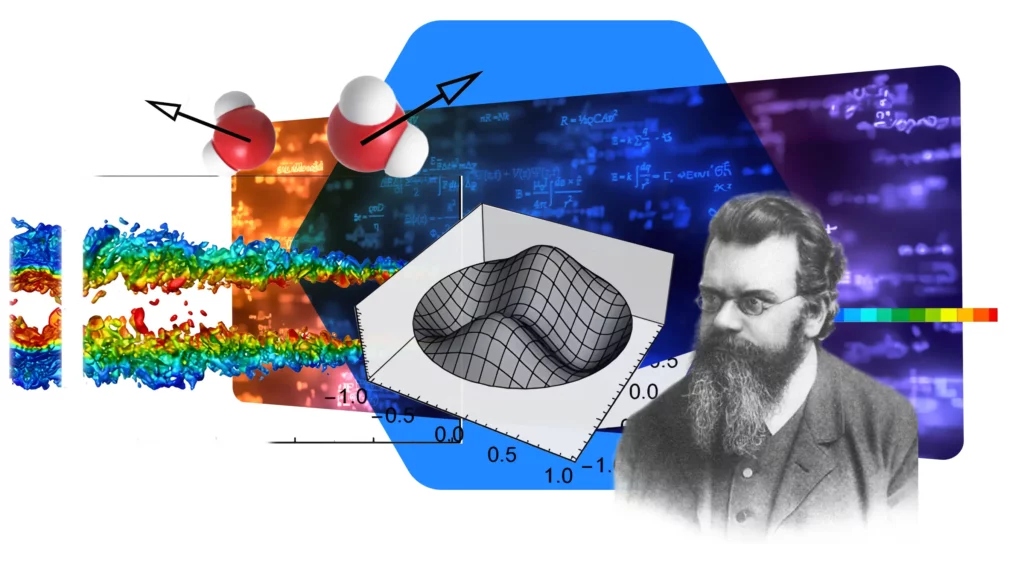

For certain industrial processes where, complex multi-physics is involved, it becomes impossible to solve problems using a single approach – which demands coupling of different methods. This process, called hybridization, is crucial for COA-CFD as we democratize solutions that are otherwise usable only by experts of the domain.

Process behind hybridization

Hybridizing multiple solvers isn’t straightforward—it involves addressing complex interdependencies between physical quantities such as mass, forces, temperature, and electrostatic potential, among others. For example, Top coating – one of the use cases in COA-CFD – needs to accurately calculate forces on a paint droplet, that are constantly dependent on gravity, air drag and electrostatic forces. A deep understanding of the top coating process, fluid mechanics, electrostatics, and careful modelling was essential to calculate these forces accurately, and then integrate the droplet trajectory. Furthermore, to check for errors, multiple rounds of testing and validation is conducted using real-world data from automotive OEMs.

Computational challenge

One of the biggest challenges in hybridized solvers is the computational cost. The COA-CFD project leverages cutting-edge technology like multi-GPU setups and parallel processing to handle these complex computations efficiently. By decomposing tasks and distributing them across multiple GPUs, we have dramatically reduced computation times without compromising accuracy. This further helps in offering cloud-based online access.

Milestone: Top coating simulation

The completion of our Top Coating solution is a key milestone achievement in the COA-CFD project. This milestone demonstrates the successful hybridization of four different solvers— Lattice Boltzmann Method (LBM), Finite Difference Method (FDM), Lagrangian Particle Method, and Thin Film Solver—into a single, cohesive framework. This solution not only accurately captures the real-world physics of top coating but also sets the stage for applying similar techniques to other industrial processes, like powder coating, and spray waxing.

Top Coating Simulation using hybrid solvers by ess PaintShop.

Conclusion

As we continue to develop the COA-CFD platform, we will keep refining our hybridization techniques to ensure even more accurate and faster simulations for complex industrial applications. The democratization of CFD software remains at the heart of our efforts, ensuring that users across various industries can easily implement and benefit from cutting-edge fluid dynamics simulations. Stay tuned for further updates!